Quality Control

How We Maintain Consistency Before Every Watch Leaves Our Hands

Quality control exists to answer a simple question: what actually happens to a watch before it reaches you. In replica watch production, variation is unavoidable. Even within the same version and model, individual differences appear. Final-stage quality control is not about finding a perfect example. It is about preventing issues that should not occur and ensuring consistent, predictable results across individual pieces.

Why Quality Control Matters at the Final Stage

Replica watches are produced in batches, not as single handcrafted pieces. As a result, variation appears even when the reference, factory, and version remain unchanged. Some differences are acceptable. Others are not.

Final-stage quality control focuses on consistency rather than perfection. The goal is not to elevate one watch above all others, but to ensure that each watch meets a defined standard before it leaves our hands. Issues that are visible, functional, or likely to escalate with normal use are filtered out at this stage. What remains should behave consistently, not exceptionally.

Incoming Inspection

Incoming inspection serves as an entry gate. It is designed to identify obvious abnormalities before assembly rather than perform deep technical evaluation.

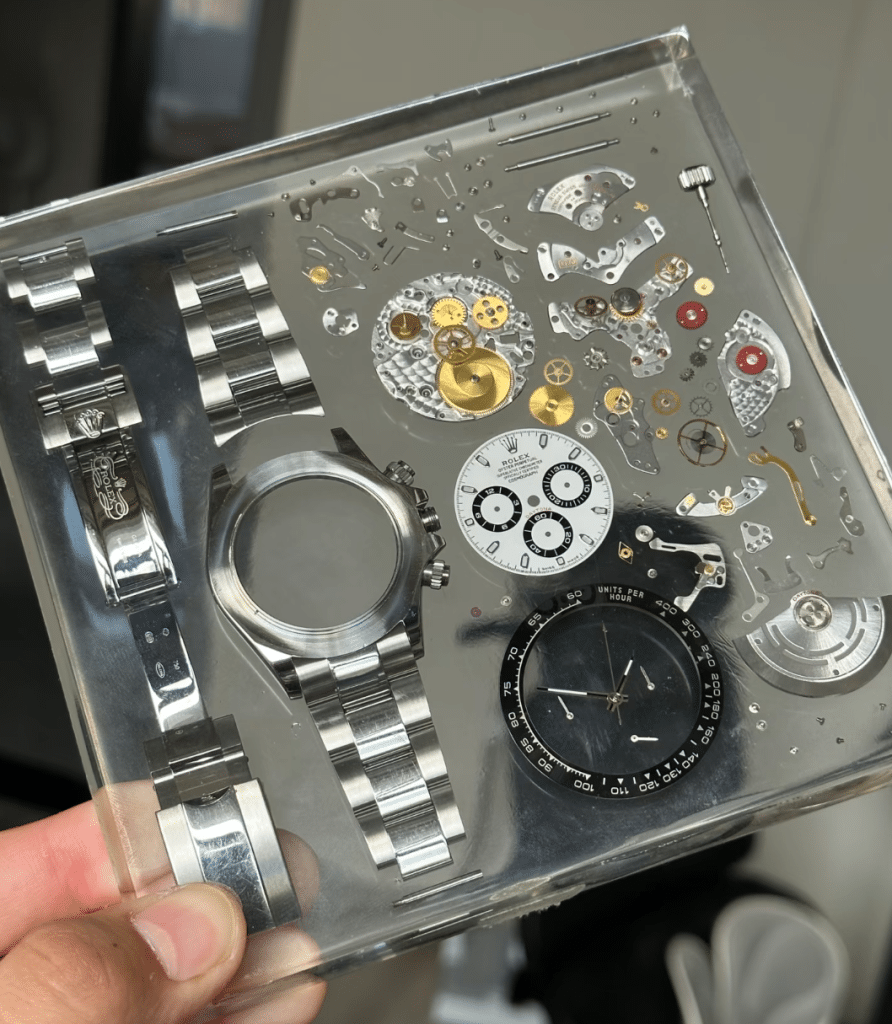

Component-Level Initial Check

Key components are reviewed as individual parts before assembly. The case, bezel, dial, bracelet, and clasp are examined separately to identify irregularities that would compromise assembly or final appearance.

This stage focuses on identification rather than correction. Parts that show clear deviation are flagged and filtered out early. The purpose is not to evaluate fine accuracy, but to prevent unsuitable components from progressing further into the process.

Surface, Dimensions, and Materials

Surface inspection looks for visible scratches, impact marks, uneven brushing, or abnormal polishing that cannot be corrected through assembly. Dimensional checks focus on whether parts fall within reasonable tolerance ranges rather than matching theoretical specifications.

Material consistency is assessed visually and by handling. Finishing tone, surface response, and tactile feedback should align across components. Laboratory testing is not part of this stage. The emphasis is on consistency that can be verified through direct observation.

Assembly & Functional Testing

This stage focuses on functional reliability after the watch is fully assembled. The objective is to observe behavior, not to document specifications.

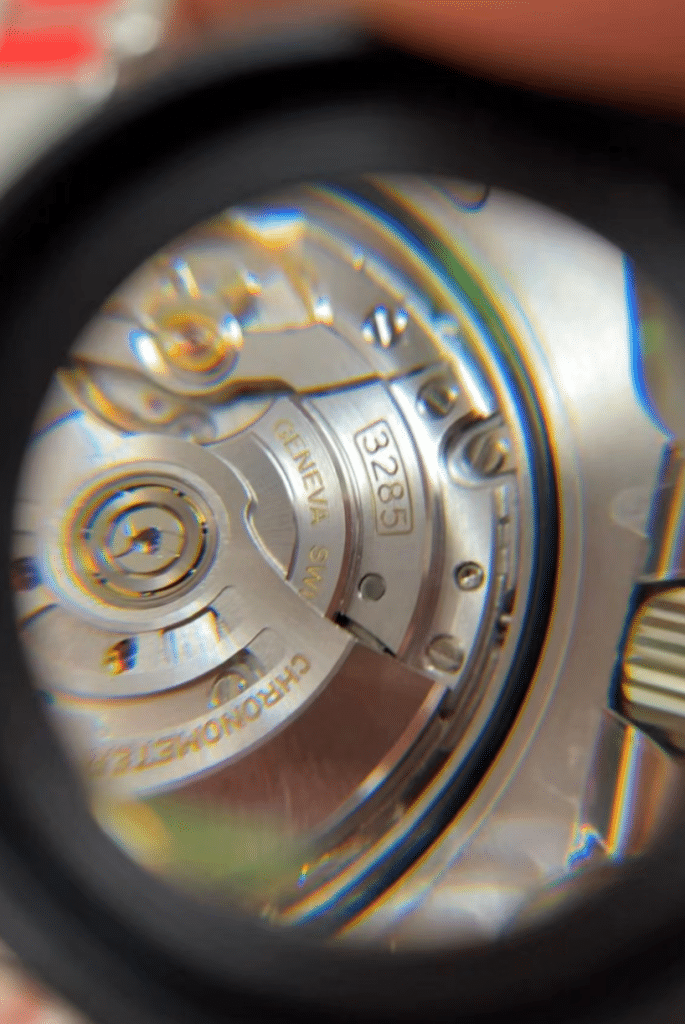

Winding and Timekeeping Behavior

Manual winding is tested to ensure smooth engagement and consistent resistance. Irregular feedback often indicates friction or improper interaction within the movement.

Timekeeping is observed across normal use conditions rather than judged by single static readings. Stability matters more than isolated accuracy. A watch that behaves predictably is prioritized over one that only performs well under controlled measurement.

Chronograph Function Testing (Where Applicable)

On chronograph models such as the Daytona, functional testing focuses on operation response. Start, stop, and reset actions are repeated to confirm clean engagement and return behavior.

The emphasis is on tactile response and consistency. Hesitation, misalignment, or inconsistent reset behavior are treated as functional issues rather than cosmetic ones.

Basic Regulation and Adjustment

Final-stage regulation is limited and intentional. Adjustments are made only where necessary to support stable daily wear.

This is not a deep tuning process and does not aim to push performance to extreme targets. The objective is to ensure reasonable balance and reliability under normal use conditions.

Visual & Detail Check

Visual inspection is performed from two perspectives: first impression and long-term viewing.

Dial Elements and Markers

Hour markers are checked for seating height, spacing, and visual alignment. The focus is on consistency when viewed naturally rather than microscopic precision.

Minor variation may exist, but elements that disrupt overall balance or draw unintended attention are not accepted.

Lume Application

Lume is assessed for even fill and natural color tone. Application should appear consistent across markers and hands without obvious overflow or gaps.

Brightness values are not measured. The goal is uniform appearance and acceptable night visibility rather than peak intensity.

Crystal, Hands, and Alignment

The crystal is checked for visible defects, distortion, or irregular edge behavior. Hand clearance is verified to ensure no interference during operation.

Alignment is evaluated from realistic viewing angles rather than fixed inspection positions. Visual balance takes priority over theoretical centering.

Final Review Before Shipping

This stage represents a responsibility checkpoint rather than a procedural formality.

Overall Consistency Check

The watch is reviewed as a complete object. Bracelet articulation, crown operation, and overall visual balance are reassessed after all prior steps are completed.

The final judgment is whether the watch meets a consistent clean-level standard. Watches that fall short are reworked or withheld rather than passed through.

What Quality Control Is — and Is Not

Quality control does not eliminate all variation, and it does not guarantee perfection. It does not protect against every future risk or replace normal wear considerations.

What it does is reduce avoidable issues and filter out problems that are visible, functional, or reasonably predictable. Its role is defined, limited, and necessary.

How This Process Supports

This quality control process reflects a consistent standard and a defined sense of responsibility. It supports how we approach long-term trust without overstating what inspection alone can achieve.